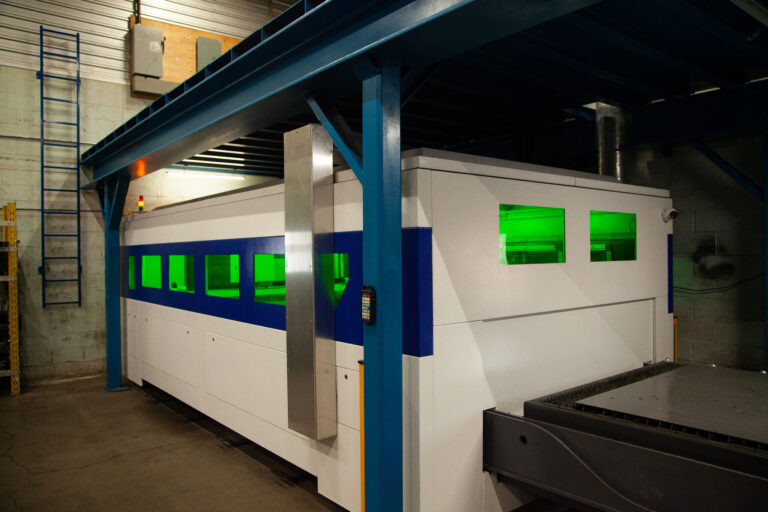

FABCAN (FS) Flat Sheet Fiber Optic Laser

Built for serious production, our flat sheet laser cutting machines combine intelligent motion control, high-power cutting heads, and a rigid welded steel bed to deliver clean, accurate results on every cut.

Intelligent High Power Cutting Heads

FAB CAN Lasers are powered by BLT4 BLT6 and BLT9 Series high power cutting heads.

Advanced Micro Joint Feature

HYPCUT software has an advanced micro-joint feature that easily create tabs on all thicknesses of steel

Smart Laser Off

Monitor the processing to smartly turn off the laser, realize a slag-free cutting with no gap.

Cut Path Monitoring

Cut path monitoring feature

Smart Piercing

Flat piercing, smooth pierce, multi-stage piercing or smart piercing

Auto Recut

When real-time in-head sensor detects the plate was not cut through, the cutting head will automatically do recut.

Stage-9 Piercing

Support ultra-thick plate piercing with better performance.

Machine Features

Heavy Duty Plate Welded Machine Bed

A welded plate heavy work bed is an excellent choice for laser cutting machines that require ultra-high power, such as those boasting a 40,000 watt capacity. The added weight of the work bed improves the cutting speed and overall performance of the machine.

Its stiff and stable base frame provides a robust foundation for laser cutting, ensuring precision and accuracy even during high-speed operations.

This type of work bed can facilitate faster cutting without compromising quality or accuracy. The welded plate construction reduces vibration and noise, creating a more comfortable and safe working environment for machine operators and other employees.

In summary, a welded plate heavy work bed is an ideal investment for anyone seeking enhanced performance and efficient laser cutting.

Extruded Aluminum Gantry

When it comes to machine gantry one material stands out for its exceptional properties, and that material is aerospace-grade aluminum. Produced to meet strict industry standards and extruded in a 4,300 ton press, this material boasts a unique combination of high strength and ultra-lightweight design.

Aerospace aluminum’s low weight is a definite advantage, as it can significantly reduce the weight of a gantry. Additionally, this material’s rigidity increases the stiffness and stability of a structure, making it a vital component in critical applications where lightweight and durability are of utmost importance.

Beyond its weight and rigidity, aerospace aluminum can also increase machine speed, thanks to its ability to withstand high speeds and stresses. This makes it possible to manufacture components that can endure high loads, enabling machines to operate more efficiently and effectively.

By leveraging this cutting-edge material, we can take the capabilities of to the next level, achieving new heights of performance and reliability.

Exchange Table

The incorporation of the Fast Up and Over table in a fiber laser machine brings significant benefits in terms of time savings and operational efficiency.

By using the fast Up and Over mechanism reduces the number of moving parts involved in the table change system. This simplified approach not only enhances reliability but also minimizes the risk of encountering technical issues or malfunctions that could disrupt the laser cutting Machine.

This innovative feature improves workflow and minimizes down time, allowing operators to achieve high-quality laser-cut products more efficiently.

Software Features

Intelligent HypCut Nesting Software

Multiple piercing solutions for metal sheet of different thickness; piercing slag removal; vibration suppression; close-loop gas control; Separate layer technique for large, medium and small contour cutting, all to expand the machine production capability.

Speed: acceleration up to 5G

- Find edge: up to 1800inch/min high speed with precision find sheet edge, optional find edge patterns to meet your production needs.

- File formats: support direct production of DXF and G code; support fast process of LXDS and NRP file generated by CypNest.

- Assist functions: quick cut-off remnant sheet, auto nozzle cleaning, auto lubrication, Auto pallet changes, ect.

- Accuracy: theoretical path accuracy ±0.005”, positioning accuracy ±0.005”, repositioning accuracy ±0.005”.

- Algorithm: adopt asymmetrical acceleration and deceleration algorithm, reduce machine impact and prolongs machine Life.

Integrated nesting software sends programs directly to the machine instead of a network share

FSCUT8000 EtherCAT bus system

The FSCUT8000C EtherCAT CNC Control System is a cutting-edge CNC controller designed to provide superior cutting performance and accuracy. Its advanced EtherCAT communication technology ensures fast and reliable data exchange between different components, resulting in a stable and high-speed operation. The system’s high-powered and intelligent cutting head delivers precise cuts on various materials, making it suitable for a wide range of cutting applications. With the FSCUT8000 EtherCAT CNC Control System, you can expect optimal cutting results and maximum efficiency in your operations.

No Software Fees

Nesting software and CNC controller are tightly integrated and creates a seamless software integration

Benefits

Fast Pallet Changer

feature

Up and over table fast pallet change in as little as 16 seconds

Quick Lens Replacement

feature

Replaceable cutting head lens onsite reduces machine downtime to hours from days

Corner Power Control

feature

Intelligent corner power control on the laser head saves on cut assist nitrogen gas

Cleaner Cuts

feature

Cleaner cuts due to improved cutting technology in software

CSA Safety Inspection

support

A CSA approved safety inspection is included with the installation of each machine

Total Cost of Ownership

support

Choose FABCAN for a 30 – 50% cost savings vs name brands

Phone Support

support

Free phone support is included

Quick Edge Detection

feature

Quick advanced edge detection on rectangle, round and L-shaped materials.

Machine Specifications

Bed Size

Model FS1530

Model FS1540

Model FS2040

Model FS2050

Model FS2560

Model FS2580

Max Material Size:

5 ft x 10 ft

5 ft x 12 ft

6 ft x 12 ft

6 ft x 16 ft

8 ft x 20 ft

8 ft x 24 ft

Actual Table Size:

62 in x 122 in

62 in × 144 in

74 in × 146 in

74 in × 194 in

98 in × 242 in

98 in × 290 in

Model FS1530

Max Material Size:

5 ft x 10 ft

Actual Table Size:

62 in x 122 in

Model FS1540

Max Material Size:

5 ft x 12 ft

Actual Table Size:

62 in × 144 in

Model FS2040

Max Material Size:

6 ft x 12 ft

Actual Table Size:

74 in × 146 in

Model FS2050

Max Material Size:

6 ft x 16 ft

Actual Table Size:

74 in × 194 in

Model FS2560

Max Material Size:

8 ft x 20 ft

Actual Table Size:

98 in × 242 in

Model FS2580

Max Material Size:

8 ft x 24 ft

Actual Table Size:

98 in × 290 in

Laser Power Output

Laser Power Output

3 kW

4 kW

6 kW

8 kW

10 kW

12 kW

15 kW

20 kW

30 kW

40 kW

60 kW

Laser Power Output

Laser Power Output

3 kW

4 kW

6 kW

8 kW

10 kW

12 kW

15 kW

20 kW

30 kW

40 kW

60 kW

Finance with Easy Lend

We offer financing to our customers through Easy Lend.

Easy Lend offers the most competitive rates across Canada. Even if you do not meet traditional lending criteria, Easy Lend can accommodate you through specialized programs.

Call (647) 562-4201 x 101, or complete a credit application.After emailing or faxing the completed application back to Easy Lend, a representative will get in touch shortly.